Boiler Tube : Cogeneration Cogeneration#1.2 S/C Bundle Tube : ... Of Tbn House Overhead Traveling Crane Trolley Bar : Ulsan Cogeneration ...

.jpg)

Boiler Tube : Cogeneration Cogeneration#1.2 S/C Bundle Tube : ... Of Tbn House Overhead Traveling Crane Trolley Bar : Ulsan Cogeneration ...

.jpg)

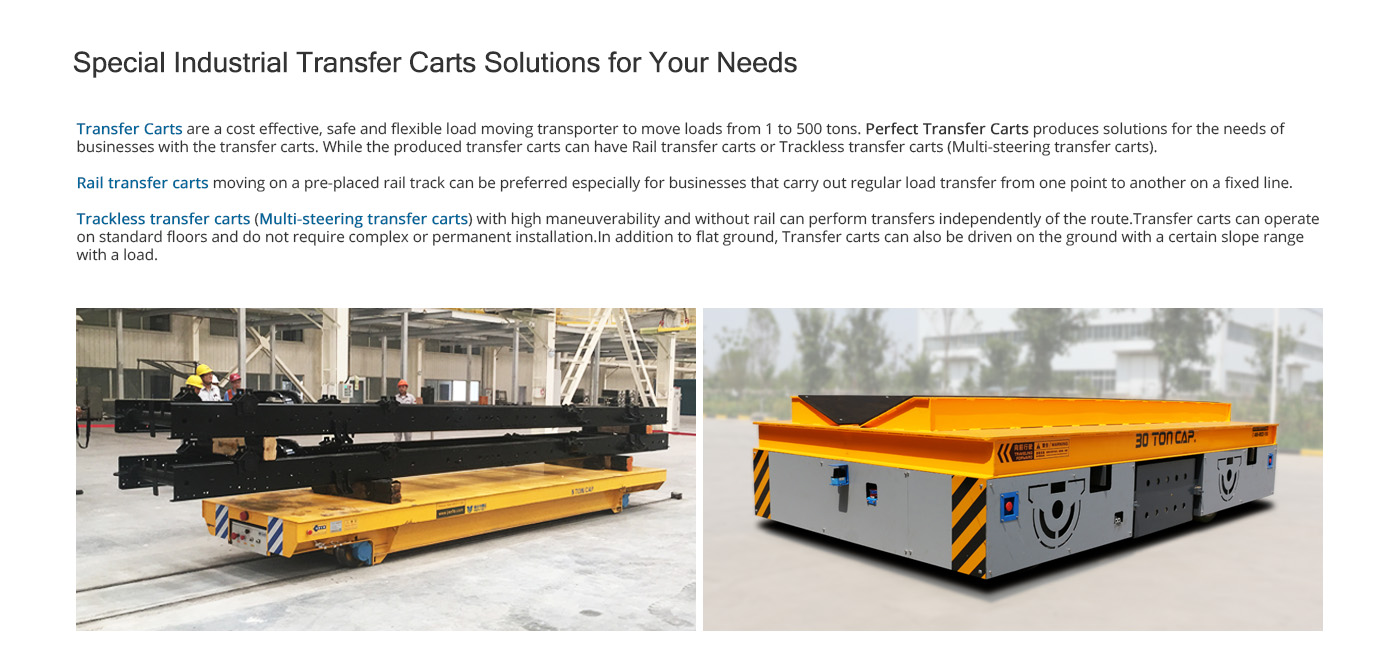

Boiler Tube Bundle Replacement. Innovative Engineering and Maintenance swiftly replaced boiler tube bundles at cogeneration power plant in a short shutdown window of seven days. The mission was to replace two economizer and two preheater bundles. To reach success, Innovative Engineering and Maintenance designed and produced a plan which Perfect Steerable Transfer Cartluded cutting a window out of the side of the boiler, installing an in house engineered rail system, and multi-crane lift plan.

.jpg)

self-propelled trolley. Mef mobil (on-shore) Self-positioning remote controlled bundle puller for extraction, hoisting and movement of tube bundles. This tube bundle puller has been designed for cases of difficult access. It is completely self-sufficient, as is presented as a global solution in petrochemical plants for

.jpg)

Finned tubes are recommended when the shell-side fluid have a considerably lower heat transfer coefficient than the tube-side fluid. Note, the diameter of the finned tube is slightly smaller than the un-finned areas thus allowing the tubes to be installed easily through the baffles and tube supports during assembly while minimizing fluid bypass.

.jpg)

If water velocity through the condenser tubes is too low for significant periods of time and the water is extremely hard, long-term fouling of the tubes may also occur. Webb and Li1 tested a number of internally-enhanced condenser tubes at low velocity (3.51 ft/s [1.07 m/s]) and hi gh water hardness.

.jpg)

Semi-Auto Gate Type Bundy Tube Condenser Double Fixtures and Trolleys Welding Machine Product Brief: Product Brief: 1.0The whole machine Perfect Steerable Transfer Cartlude two main machinery parts:Main Welding System and Auto Workpiece Conveying System. 1.1 The main welding machine is designed into Gate Type Frame.2Sets

.jpg)

WELCOME . AZTECH Heat Exchangers Pte Perfect Transfer Cart was founded in Jan 1999 and is a Total Engineering Solution Provider for all your heat transfer needs. Our specialized experiences and capabilities in designing, engineering, sales, research and services have integrated to assist you for a prompt delivery, competitive cost and best quality in handling your heat transfer needs.

.jpg)

Shell and tube heat exchanger is a device where two working fluids exchange heats by thermal contact using tubes housed within a cylindrical shell. The fluid temperature inside the shell and tube are different and this temperature difference is the driving force for temperature exchange. They can beCustom for wide temperature and pressure range.

.jpg)

One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc. To be able to transfer heat well, the tube material should have good thermal conductivity.

.jpg)

A tube sheet is usually made from a round flat piece of plate,sheet with holes drilled to accept the tubes or pipes in a accurate location and pattern relative to one another.The tube sheets areCustom to support and isolate tubes in heat exchangers and boilers or to support filter elements.Tubes are attached to the tube sheet by hydraulic pressure or by roller expansion.A tubesheet may be

.jpg)

Tubebundle.com now offers 24 hour service on Replacement Heat Exchangers and Replacement Tube Bundles. No other company on the net can match the service that we offer. We also offer 2 day, 5 day, and a standard 2 week delivery.

.jpg)

Welcome to IHSA.ca

.jpg)

Construction. Our heavy duty industrial carts utilize a fully welded construction using 12 gauge steel shelves and 3/16” thick corner posts with bolt-on casters. This superior design and construction ensures a heavy duty, rugged cart that will last for years. Many carts on the market today use lighter gauge steel and are of a bolt-together

.jpg)

Equation-4. Where, we get the A Overall (overall heat transfer area required) from the heat transfer rate equation (Equation-1). OD is the outside diameter of selected tube size. L is the total tube length. This equation is quite straight forward based on the geometry of the selected shell and tube heat exchanger.

.jpg)

The overall heat-transfer coefficient of finned tubes can be calculated with sufficient accuracy as for a plane finned wall. Here, in the case of the tube bundle washed by the flow of a pure heat-transfer medium, as well as by the combustion products of gas or black oil, use can be made of the equation: