Jul 24, 2014 · Slag Pot Transfer High Temperature Proof Rail Ladle Carrier Transport Contact now 150t Electric Ladle Transfer Car with Weighing SensorCustom (KPC-150T)

.jpg)

Jul 24, 2014 · Slag Pot Transfer High Temperature Proof Rail Ladle Carrier Transport Contact now 150t Electric Ladle Transfer Car with Weighing SensorCustom (KPC-150T)

.jpg)

Position & Press. Place the transfer face down on the garment. For 100% cotton or cotton/poly blends (365°F): Close the heat press and heat for 4-6 seconds. For 100% polyester (325-335°F): Close the heat press and heat for 10-12 seconds.

.jpg)

The electric transport trolley uses the motor as its driving force, and the on-board control box as its control system. Therefore, when the explosion-proof paint booth transport trolley isCustom in the paint spraying room, the explosion-proof treatment shall be adopted where there is current passing through.

.jpg)

Transfer Car and Trolley. Remso is the leading supplier of small andPerfect capacity of Transfer Car to transport the metals and associated industries. Ladle Transfer Car, Flame Guard Trolleys of various capacities along with stands to handle ladles up to 500 MT capacities have been supplied complete with gear box, motors and electric panels.

.jpg)

Electric hoistCustom separately or in combination with single beam, hoist double girder crane, gantry crane, cantilever crane and others, widelyCustom in railways, docks, industrial and mining enterprises, warehouses and other places for lifting heavy objects.It devides into Single speed wire rope electric hoist (CD 1), Double speed wire rope electric hoist (MD 1), and new designed wire rope

.jpg)

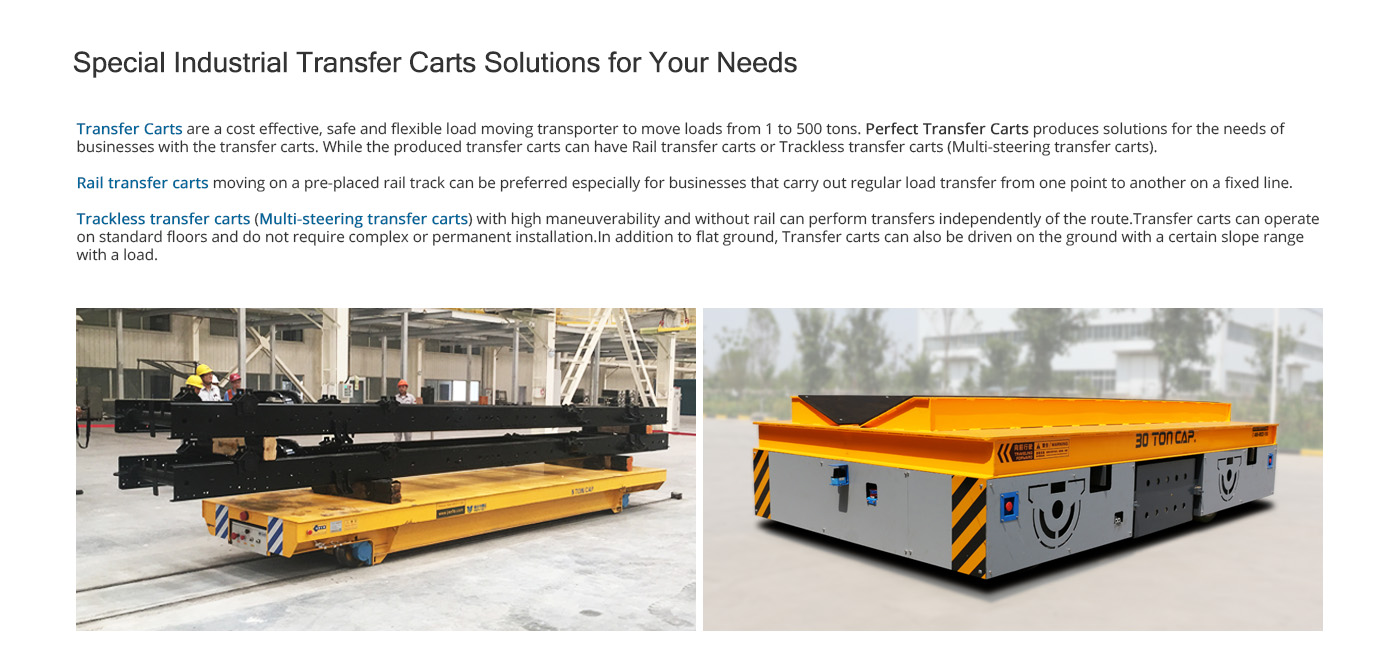

the hot metal ladle transfer car is a ladle transfer cart for molten steel. it is an electric flat cart, which is a traditional generallyCustom transfer trolley. more importantly, it has become a new hot spot in the global industrial transportation field and market. especially suitable for heavy workshop transportation.

.jpg)

On-rail Transfer trolleys. 35t battery powered steel pipe transfer trolley on rail Steel pipe transfer trolley on rail tracks High temperature explosion-proof aluminum transfer hot metal molten iron steel ladle transfer car Heavy Load Material Rail Flatbed Transfer Carts For Metallurgy Factory Heavy Die transfer car Electric Motor Driven Rail Flatbed Transfer trolley For Industry Foundry Parts

.jpg)

Steel Mill Feeding Crane. The feeding crane isCustom to add charge to the open hearth. The lower end of the column of the main trolley is equipped with a picking rod, which isCustom to pick up the material box and send it into the furnace. The main column can rotate around a vertical axis, and the pick rod can swing up and down and rotate.

.jpg)

heavy load transfer car for metaurllgy plant 200 tons-Perfect Our Cars can handle the full range of your mill-duty transfer car needs, whether you need a 250-ton capacity slag pot

.jpg)

DB Machine Tools Pvt. Perfect Transfer Cart. has been a leading supplier of rolling mills and rolling mill ancillary and support equipment for many years. Thermomechanical processing, also known as thermo-mechanical treatment (TMT), is a metallurgical process that integrates work hardening and heat-treatment into a single process.

.jpg)

Rail Transfer Trolley for sale, Quality Explosion Proof High-Temperature-Resistant 8 Tons Rail Flat Car on sale of Henan Perfect Intelligent Technology Co., Perfect Transfer Cart. from China.

.jpg)

Popular Products of Heavy Load Battery Power,40 Tons Anti - High Temperature Die Rail Transfer Trolley by Rail Transfer Trolley - Henan Perfect Intelligent Technology Co., Perfect Transfer Cart. from China.

.jpg)

Metallurgical Casting Overhead Crane is applicable to - 10 ℃ to + 50 ℃, environment temperature, under the temperature of 40 ℃ relative humidity is not more than 50%, the lifting of the molten metal forging clasps, board of radiation temperature does not exceed 300 ℃. Working Level of job: A7, A8 isCustom in the relatively busy

.jpg)

depends on the maximum temperature to which it is exposed plus the maximum stresses to which it is subjected, also whether service is at a constant temperature or at intermittently high temperature. For a prolonged service life, such as 20 years, plain carbon steels are usually limited to a maximum operating temperature of 750°F (399°C); the ½%

.jpg)

there isCustom electroslag remelting (ESR) to 100t. After heating to the upper forging temperature the ingots are forged on a selected hydraulic press. The forge disposes of presses 30 MN, 80MN and of two presses 140 MN. After finish forging a preliminary heat treatment is performed. The aim of the heat treatment